STAINLESS STEEL ROPES:

AESTHETIC APPEARANCE MEETS POWERFUL PERFORMANCE

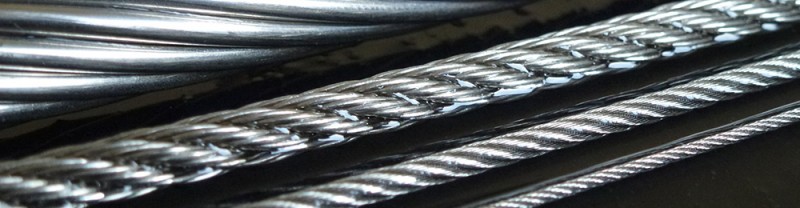

Our customers are impressed by the high quality of our stainless steel ropes time and again. The benefits are plain to see: easy maintenance and durable longevity. Our various wire rope construction types have a lot to offer as they enable the optimal product to be found for just about any area of application.

We recommend 1x19 for guy ropes as this construction type boasts low elongation and can be optimally finished with swage terminals. Or if a stainless steel thimble is to be fitted at the end of the rope, then a softer 7x7, 7x19 or even 6x36+SES construction type is recommendable. Should you wish to use the cable as a crane rope, we also deliver low-torsion 18x7 construction types. Most constructions are also available with a synthetic coating to ensure the rope causes no damage and it is additionally protected against corrosion. Learn more about the many beneficial attributes stainless steel ropes possess, our products in general as well as our unique comprehensive service offer.

COMPREHENSIVE SERVICE:

FOR INDIVIDUALISED CUSTOMER SATISFACTION

Why are we renowned among customers as being a top contact? Because due to our longstanding experience, we not only provide expert advice, we also offer comprehensive services in the area of stainless steel.

- We assist you in the selection of the optimal product

- We finish stainless steel ropes right down to the finest detail

- We are on-site to assist you during installation, if desired

As a specialised service, we also conduct alloy analyses for stainless steel products alloy analyses for stainless steel products to determine the quality and composition of your products.

Get your free consultation now

Do you have question on products, the feasibility of a project or delivery periods? Then talk to us now. Our experts will be delighted to advise you personally!

1 X 19

-

Details

Details

Rustproof stainless steel wire strand 1 x 19

- Material: 1.4401

nominal diameter

mmweight kg per 100 m tensile strength

N/mm²calculated breaking load

kNminimum breaking load

kN0,54 0,10 1570 0,27 0,24 1,00 0,50 1570 0,94 0,82 1,25 0,70 1570 1,46 1,29 1,50 1,10 1570 2,11 1,86 1,80 1,60 1570 3,04 2,67 2,00 2,00 1570 3,75 3,30 2,50 3,10 1570 5,86 5,15 3,00 4,50 1570 8,43 7,42 3,50 6,10 1570 11,48 10,10 4,00 8,00 1570 14,99 13,19 5,00 12,40 1570 23,43 20,62 6,00 17,80 1570 33,74 29,69 7,00 24,30 1570 45,92 40,41 8,00 31,70 1570 59,98 52,78 10,00 49,50 1500 89,54 78,79 12,00 71,30 1450 124,63 109,68 14,00 97,10 1340 156,77 137,96 16,00 127,00 1340 204,76 180,19 19,00 178,80 1260 271,51 238,93 nominal diameter

mmweight kg per 100 m tensile strength

N/mm²calculated breaking load

kNminimum breaking load

kN0,54 0,10 1570 0,27 0,24 1,00 0,50 1570 0,94 0,82 1,25 0,70 1570 1,46 1,29 1,50 1,10 1570 2,11 1,86 1,80 1,60 1570 3,04 2,67 2,00 2,00 1570 3,75 3,30 2,50 3,10 1570 5,86 5,15 3,00 4,50 1570 8,43 7,42 3,50 6,10 1570 11,48 10,10 4,00 8,00 1570 14,99 13,19 5,00 12,40 1570 23,43 20,62 6,00 17,80 1570 33,74 29,69 7,00 24,30 1570 45,92 40,41 8,00 31,70 1570 59,98 52,78 10,00 49,50 1500 89,54 78,79 12,00 71,30 1450 124,63 109,68 14,00 97,10 1340 156,77 137,96 16,00 127,00 1340 204,76 180,19 19,00 178,80 1260 271,51 238,93

7 X 7

-

Details

Details

Rustproof stainless steel wire rope 7 x 7

- Material: 1.4401

nominal diameter

mmweight kg per 100 m tensile strength n/mm2 calculated breaking load

kNminimum breaking load

kN0,54 0,12 1570 0,20 0,16 0,68 0,18 1570 0,31 0,26 0,72 0,21 1570 0,35 0,29 0,81 0,26 1570 0,44 0,37 1,00 0,40 1570 0,68 0,56 1,25 0,50 1570 1,06 0,88 1,35 0,72 1570 1,24 1,03 1,50 0,90 1570 1,53 1,27 1,80 1,30 1570 2,20 1,83 2,00 1,60 1570 2,71 2,25 2,50 2,50 1570 4,24 3,52 3,00 3,50 1570 6,10 5,07 3,50 4,82 1570 8,31 6,90 4,00 6,30 1570 10,85 9,02 5,00 9,80 1570 16,96 14,09 6,00 14,2 1570 24,42 20,29 7,00 19,3 1570 33,23 27,62 8,00 25,2 1570 43,41 36,07 10,00 39,3 1570 67,82 56,36 12,00 56,6 1570 97,67 81,16 nominal diameter

mmweight kg per 100 m tensile strength n/mm2 calculated breaking load

kNminimum breaking load

kN0,54 0,12 1570 0,20 0,16 0,68 0,18 1570 0,31 0,26 0,72 0,21 1570 0,35 0,29 0,81 0,26 1570 0,44 0,37 1,00 0,40 1570 0,68 0,56 1,25 0,50 1570 1,06 0,88 1,35 0,72 1570 1,24 1,03 1,50 0,90 1570 1,53 1,27 1,80 1,30 1570 2,20 1,83 2,00 1,60 1570 2,71 2,25 2,50 2,50 1570 4,24 3,52 3,00 3,50 1570 6,10 5,07 3,50 4,82 1570 8,31 6,90 4,00 6,30 1570 10,85 9,02 5,00 9,80 1570 16,96 14,09 6,00 14,2 1570 24,42 20,29 7,00 19,3 1570 33,23 27,62 8,00 25,2 1570 43,41 36,07 10,00 39,3 1570 67,82 56,36 12,00 56,6 1570 97,67 81,16

7 X 19

-

Details

Details

Rustproof stainless steel wire rope 7 x 19

- Material: 1.4401

nominal diameter

mmweight kg per 100 m tensile strength

N/mm2calculated breaking load

kNminimum breaking load

kN1,50 0,86 1570 1,48 1,28 2,00 1,50 1570 2,63 2,27 2,50 2,30 1570 4,10 3,55 3,00 3,50 1570 5,91 5,12 4,00 6,10 1570 10,50 9,09 5,00 nominal diameter

mmweight kg per 100 m tensile strength

N/mm2calculated breaking load

kNminimum breaking load

kN1,50 0,86 1570 1,48 1,28 2,00 1,50 1570 2,63 2,27 2,50 2,30 1570 4,10 3,55 3,00 3,50 1570 5,91 5,12 4,00 6,10 1570 10,50 9,09 5,00

8 X 7+PPC

-

Details

Details

Rustproof stainless steel wire rope 8 x 7+PPC

- Material: 1.4301

nominal diameter

mmweight kg per 100 m tensile strength

N/mm2calculated breaking load

kNminimum breaking load

kN6,50 14,80 1770 25,05 21,76 8,00 22,30 1770 37,95 32,96 10,00 34,00 1770 59,30 51,51 nominal diameter

mmweight kg per 100 m tensile strength

N/mm2calculated breaking load

kNminimum breaking load

kN6,50 14,80 1770 25,05 21,76 8,00 22,30 1770 37,95 32,96 10,00 34,00 1770 59,30 51,51

6 X 19+PPC

-

Details

Details

Rustproof stainless steel wire rope 6 x 19+PPC

- Material: 1.4401

nominal diameter

mmweight kg per 100 m tensile strength

N/mm2calculated breaking load

kNminimum breaking load

kN8,00 22,15 1570 35,87 30,85 10,00 34,60 1570 56,05 48,20 nominal diameter

mmweight kg per 100 m tensile strength

N/mm2calculated breaking load

kNminimum breaking load

kN8,00 22,15 1570 35,87 30,85 10,00 34,60 1570 56,05 48,20

6 X 36+IWRC

-

Details

Details

Rustproof stainless steel wire rope 6 x 36+IWRC

- Material: 1.4401

nominal diameter

mmweight kg per 100 m tensile strength

N/mm2calculated breaking load

kNminimum breaking load

kN8,00 24,00 1570 46,22 35,77 10,00 38,00 1570 72,22 55,89 12,00 54,70 1570 104,00 80,48 14,00 74,50 1570 141,55 109,55 16,00 97,30 1570 184,88 143,08 18,00 123,00 1570 33,99 181,09 20,00 152,00 1570 288,88 223,57 22,00 282,00 1570 349,54 270,52 24,00 240,00 1570 415,99 321,94 26,00 282,00 1570 488,21 377,83 nominal diameter

mmweight kg per 100 m tensile strength

N/mm2calculated breaking load

kNminimum breaking load

kN8,00 24,00 1570 46,22 35,77 10,00 38,00 1570 72,22 55,89 12,00 54,70 1570 104,00 80,48 14,00 74,50 1570 141,55 109,55 16,00 97,30 1570 184,88 143,08 18,00 123,00 1570 33,99 181,09 20,00 152,00 1570 288,88 223,57 22,00 282,00 1570 349,54 270,52 24,00 240,00 1570 415,99 321,94 26,00 282,00 1570 488,21 377,83

PVC-COATED STAINLESS STEEL WIRE STRANDS/ROPES

-

Details

Details

PVC-Coated stainless steel wire strands and ropes

- Material: 1.4401

color 1x19

mm7x7

mm7x19

mmtransparent — 1,25/3,0 — transparent — 2,0/3,0 — transparent — 2,5/3,5 — transparent — 3,0/4,0 4,0/5,0 transparent — 3,0/5,0 — transparent — — 5,0/7,0 transparent — — 6,0/8,0 transparent — — 8,0/10,0 transparent — — 10,0/12,0 white 2,5/3,5 — — white 3,0/5,0 3,0/5,0 — white 3,0/7,0 — — white 4,0/6,0 4,0/6,0 — white — 4,0/7,0 — white 4,0/8,0 4,0/8,0 — white — 5,0/7,0 — white 5,0/8,0 5,0/8,0 — white 6,0/9,0 6,0/9,0 — color 1x19

mm7x7

mm7x19

mmtransparent — 1,25/3,0 — transparent — 2,0/3,0 — transparent — 2,5/3,5 — transparent — 3,0/4,0 4,0/5,0 transparent — 3,0/5,0 — transparent — — 5,0/7,0 transparent — — 6,0/8,0 transparent — — 8,0/10,0 transparent — — 10,0/12,0 white 2,5/3,5 — — white 3,0/5,0 3,0/5,0 — white 3,0/7,0 — — white 4,0/6,0 4,0/6,0 — white — 4,0/7,0 — white 4,0/8,0 4,0/8,0 — white — 5,0/7,0 — white 5,0/8,0 5,0/8,0 — white 6,0/9,0 6,0/9,0 —

AREAS OF DEPLOYMENT AND TYPICAL APPLICATIONS: DIVERSITY IN OUR PRODUCT PORTFOLIO

Stainless steel ropes find practical application in a broad range of areas. After all, they unite elegant looks with maximum functionality. That’s why stainless steel ropes are not only deployed in areas such as agriculture and bicycle technology, but also for architectural applications and in the yachting industry. No matter if for decorative or functional needs – or a combination of both – the spectrum of application is certainly extremely broad and can be tailored according to individual requirements.

.jpg?ts=1750244788)

...on a sunsail

...on a sunsail example 2

...with Blue Wave Terminals on a sailing yacht

...as a manure scraper rope in a cattle barn

...as a bicycle gear shifter cable

1x37 Ø 26mm stainless steel braid with rolled-on thread terminal (tension cable for pedestrian bridge)

CHARACTERISTICS: LOW MAINTENANCE AND LONG LIFE

Many, many years will pass before stainless steel ropes need replacing. In other words: high quality stainless steel ropes have a service life that’s unbeatable. And even under high loads they can also withstand quite some punishment. Due to the high chrome content (over 16%), which makes the ropes extremely resistant against corrosion, their elegant appearance remains untarnished over long intervals. The chrome combines with the air’s oxygen to form a chrome oxide or passive layer that protects the metal against surface corrosion. Nickel is added to the steel to stabilise the passive layer. Molybdenum additionally protects against pitting and crevice corrosion through chloride. In cases where some rust has nevertheless gathered, cleaning using the professional stainless steel care product Innosoft is recommendable. We are happy to advise you on this topic.